ASM Alternative Energy

Acquired by ASM Pacific Technology Ltd. (ASMPT) in 2014, the brand formerly known as ASM Alternative Energy Solar along with the solar technology portfolio from ASMPT are now united as ASM Alternative Energy. Encompassing all of the award-winning ASM Alternative Energy Solar technology and innovation developed over the last ten years combined with the product portfolio, global resources and solar innovation of ASMPT, ASM Alternative Energy leads the market in fuel cell and solar cell solutions. Technologies include market-leading solar and fuel cell metallization/printing platforms, advanced stencils and screens, SolarBlades and SolarWIS wafer inspection systems. For more information, visit www.asm-ae.com.

Products

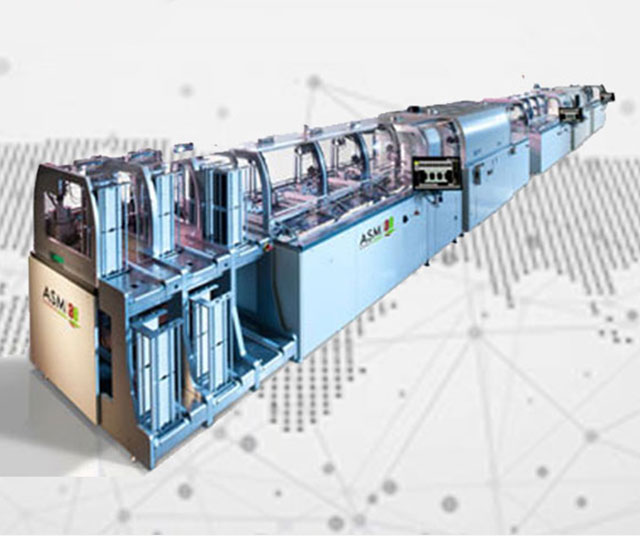

Metallization Line/ Screen Printing - Eclipse:

Highly flexible and offering a host of high performance options , Eclipse delivers unprecedented user choice . Its modular design allows manufacturers to scale up production with ease; with single and triple-head platforms extending productivity beyond throughput and into improved uptime and optimum capital utilization.

-

Process Alignment Capability: 2 CpK @ +/- 10µm

-

Breakage Rate: < 0.15%

-

Fully modular & configurable metallization line

-

Multiple print head providing parallel processing options which maximises uptime

-

Throughput configurable from 1350 to 4000 wph (subject to process and excluding scheduled downtime)

-

Topside cameras for wafer edge, fiducial or pattern alignment

-

Integrated vision inspection for ultimate process and quality control

-

Integrated breakage detection

-

Fast yet sensitive handling; high speed, zero edge contact for negligible breakage rates

-

Multiple conveying, flipping, buffering & stacking options

-

Superior positional accuracy for high yield precision

-

Industry-leading repeatability for Print on Print applications

-

Multi-language intuitive GUI control

Hou Yi

The HouYi line from ASM AE is a full metallization solution for commercial solar-cell production. Informed at every level by established solar expertise, the line combines the class-leading HouYi Screen Printer with purpose-designed loader/unloader, buffering, inspection and wafer flipping solutions.With a production capacity of 1450 wafers per hour, the HouYi line occupies a small footprint on the factory floor.

-

Process Alignment Capability: 2 CpK @ +/- 12.5µm

-

Breakage Rate: < 0.3%

-

Single lane, compact footprint

-

Perfectly balanced to operate at optimal throughput

-

Dedicated thin wafer handling

-

Handling and support mechanisms suitable for wafer thicknesses from 1mm down to 120µm

-

Compatible with wafer sizes in Square or Pseudo Square formats

-

Mimimised edge contact wafer transport

-

Delivering maximum yield and minimal waste

-

Standardised machine interface enables easy integration with inline equipment

-

Menu-driven software enables intuitive control of complex processes via full colour touch screen

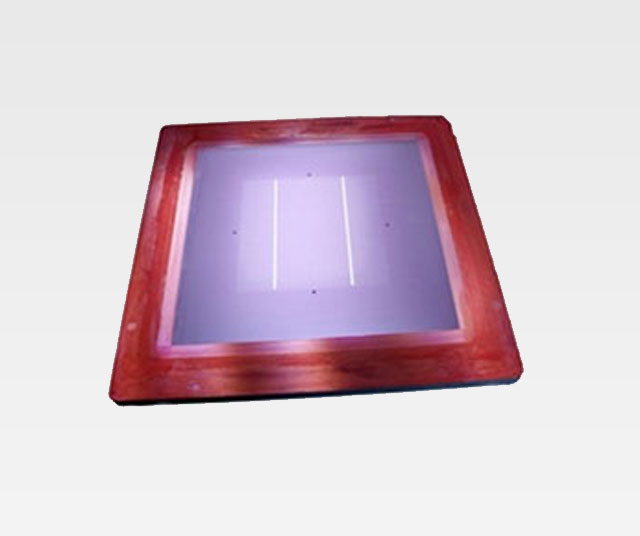

Printing Technology / Screen for the Printing - Precision Emulsion Screens

All our emulsion screens are ideal for use in advanced metallization processes. Precise material control and deposition accuracy, with the screens being produced in a Class 10,000 Clean Room with exceptional environmental and process control.

During the production process there is zero contamination and all screens are dimensionally stable.

-

Emulsion thickness 0 - 50µm ± 2µm; 51 - 100µm ± 5µm; 101 - 500 µm ±10%; 501 - 1000µm ±15%

-

Line widths from 25 µm

-

Maximum Frame size 1000 x 1000mm O/D

-

Rigorous inspection throughout the production cycle

-

Accurate verification against source data

-

Wide range of input data formats accepted

-

Premium dispatch service available on request (conditions apply)

-

Quality production and rapid turnaround

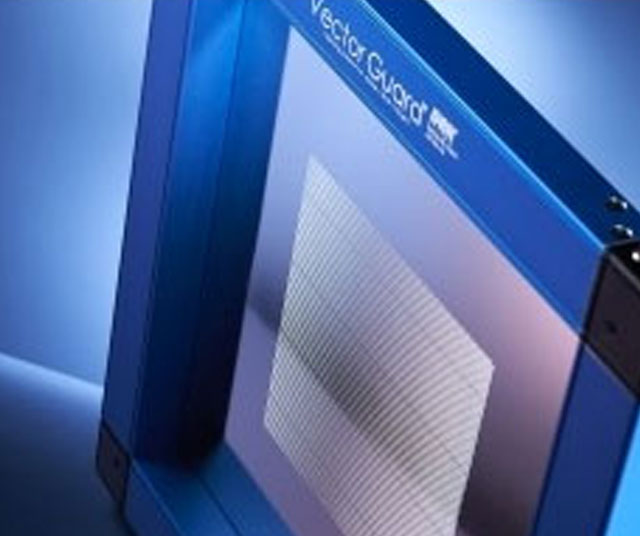

Fine line stencils

-

An increase in cell efficiency of more than 0.2% is possible, in comparison to the industry standard single screen print process.

-

Printing of front side grids with 40µm fingers, resulting in reductions of silver paste use of up to 40%, and absolute values as low as 68 mg/cell.

-

Fine Line Stencil™ can be used with printers other than those manufactured by ASM

-

The only additional knowledge required is an awareness of the process parameters and a few points on housekeeping.

-

Stencils of any standard size from 355 x 355 mm and larger can be supported. (contact ASM AE regarding other requirements)

-

Fine Line Stencil™ has a useful working life of up to 20,000 print cycles

-

Stencil thicknesses from 25µm up to 200µm are available with opening widths from 25µm upwards

-

Standard PV wafer sizes of 125mm and 156mm are easily accommodated with no lower limit on wafer size and an upper limit of 220mm for special applications