Functions and characteristics

-

Developed for multi-pole motors. The machine has two stations with a needle in each station. 2 stators are coiled simultaneously.

-

The equipment adopts a mechanic tension control system on the wire during winding.

-

It has manual loading and unloading. With security system through light curtains.

-

The HMI and touch screen where all the characteristics of the model in production, cycle time, adjustment parameters as well as machine status are visualized. The HMI also has a fault diagnosis that shows the position of the problem on the machine.

-

Adopts protection structure with aluminum profile frame.

-

The winding table is made of steel with a robust thickness for vibration absorption.

-

This concept of equipment allows easy setup between different stator settings (height, diameter, number of slots, etc.)

-

Quick tool setup;(20 minutes)Has safety curtain in the loading and unloading position and safety keys on the doors.

Specifications

-

Dimensions - 1670 * 1080 * 1790mm (length * width * height)

-

Weight - 600kg

-

Servos - 1pc Index motor, 1pc winding motor with brake

-

Voltagem - 380V/50HZ 3 fases 4 fios

-

Package height - 10-80mm standard stroke) 90-200mm (long stroke that can be customized)

-

Speed - 0 --- 500 RPM, adjustable

-

Air pressure - 0.5 --- 1Mpa

-

Diameter of electrical conductor - φ0.13 — φ1.2mm (for other specifications, inform)

-

Number of poles - multipolar

-

Diam. internal stator - φ25 — φ80mm (other specifications can be customized

-

Diam. external stator - φ50 — φ120 mm (other specifications can be customized

-

Power - 10KW

Technical Data

-

Stator O.D. - 15-95mm

-

Stator height - 8-40mm (one set of tooling can suit for stack height difference within 5mm, for example, if tooling is designed for 23mm height, then it can suit for maximum 28mm height)

-

Wire diameter - 0.4~0.8mm

-

Winding speed - Maximum 800rpm, depends on wire diameter)

-

Power supply - single phase 380V,50/60 Hz 5KW

-

Machine weight - about 500kgs

-

Dimension - 960*850*1750mm

Main Configuration

-

Controller - Panasonic

-

HMI - Weinview

-

Pneumatic componentsL - AirTac

-

Sensor - Autonics

-

Buttons - Schneider

-

Light curtain - Panasonic

-

Ball screw/linear guide - TBI/HIWIN

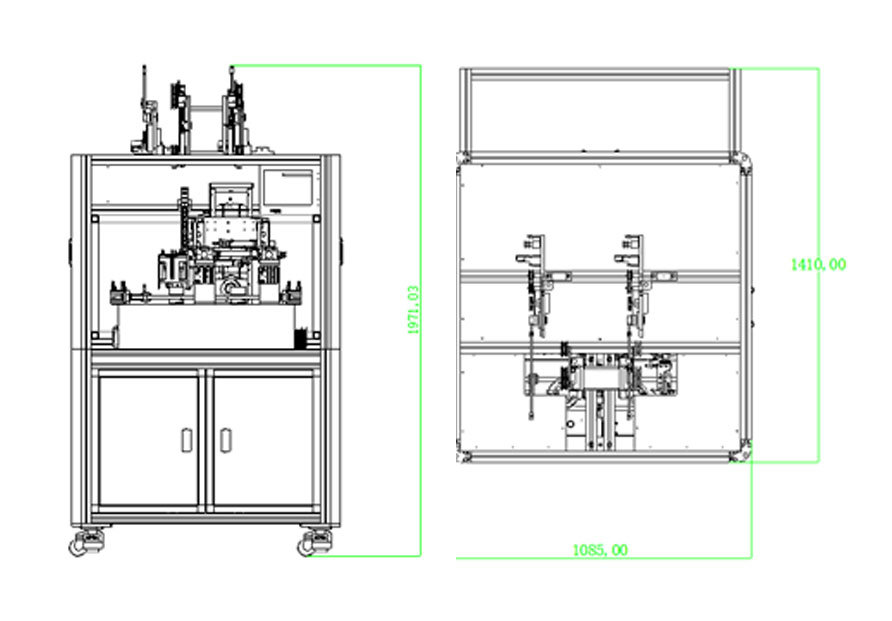

Main Technical Data

-

Wire diameter - 0.19~1.2mm

-

Swing diameter - 220mm

-

Winding head - 4pcs

-

Max stack height - 65mm

-

Max stator O.D - 120mm

-

Max speed - 2500rpm

-

Air pressure - 0.4~0.6MPa

-

Power source - 380V/50Hz

-

Weight - about 4500Kgs

-

Machine dimension - 2100*1350*2200mm

Main Components

-

Motion controller - Schndier

-

Servo motor - Schneider

-

Cylinder - AirTac

-

Sensor - Autonics

-

Switch and Button - Delixi/Schneider

-

Light curtain - Panasonic

-

Ball screw/linear guide - TBI/HIWIN

Machine Main Function and Characteristic

Machine is four winding heads with eight operation stations, high efficiency is its feature. The machine automatically put coil into transfer tool orderly, especially suitable for high production capacity requirement, high slot fill factor, small slot opening stator coil winding. Winding mode such as auto skip, auto cutting and auto indexing could be completed at one time successively; parameter can be set in HMI. Meet the 2 poles, 4 poles and 6 poles coils winding.

Spare Parts

| No. | Item | Qty | Remark |

| 01 | Nozzle | 8 pcs | Mechanical |

| 02 | Wool felt | 10 pcs | Other |

Tool

| No. | Item | Qty | Remark |

| 01 | Hex Wrench | 1 set | tool |

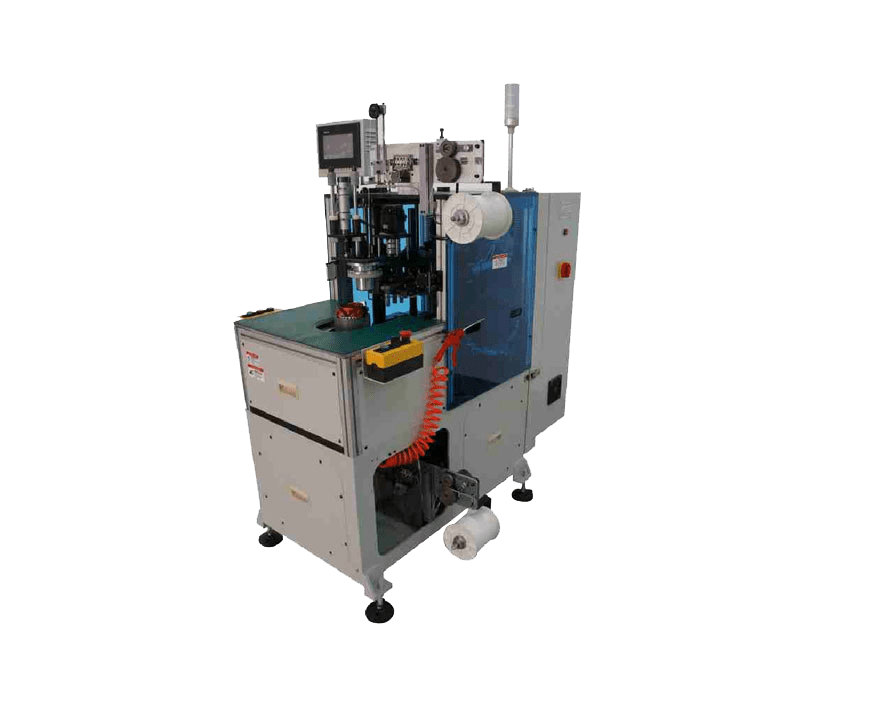

Main Technical Data

-

Stator ID - 40~100mm

-

Stator OD - Max. 160mm

-

Stack length - 30~160mm

-

Over-hang height - Max. 45mm

-

Power - 380V/50/60HZ 0.75KW

-

Machine weight - about 850kg

-

Machine dimension - L1100*W900*H1500mm

Main Components

-

Motor - Schneider

-

Sensor - Autonics

-

Pneumatic components - AirTac

-

Button/switch - Delixi/Schneider

Machine Main Function and Characteristic

-

This machine adopts servo driven system, CNC control design and HMI program.

-

The indexing is driven by servo system. Different lacing mode could be set such as slot lacing, interval lacing, fancy lacing.

-

Main spindle adopts servo control system. The rotation speed can be set.

-

Two needles driven by servo system lace upper and lower coil simultaneously.

-

Machine can automatically feed thread and cut thread. There is no need to tie a knot.

-

Tooling change is fast and convenient.

-

Lacing tension can be set.

-

Production capacity ≤1s/slot.

-

Should be no copper wire snap and wire enamel broken.

-

Primary qualification rate ≥99.5%, after rework, the rate ≥99.9%

-

This machine adopts safety grating protection system. Operator need to stand when operating.

-

Machine adopts single start button.

Spare Parts

| No. | Item | Qty | Remark |

| 01 | Lacing Needle | 2 pcs | Mechanical |

| 02 | Nozzle | 2 pcs | Mechanical |

Tool

| No. | Item | Qty | Remark |

| 01 | Hex Wrench | 1 set | tool |